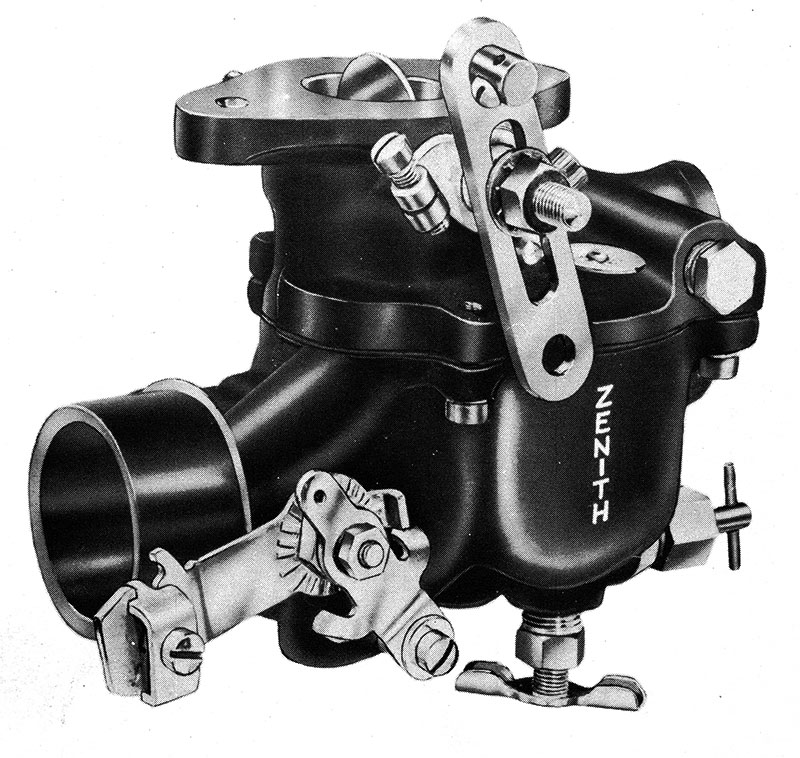

Zenith models 61, 161, 261 and 68 were updraft carburetors used on a vast number of industrial, tractor and marine applications. Production started with the model 161 in 1924 and ended in 2025 with the model 68. They were built chiefly in Zenith size 7 (SAE 3/4" nominal) and size 8 (SAE 1" nominal) though a few size 5 (SAE 5/8" nominal) carburetors were produced in the early 1940s.

Early models had cast iron bodies; late models used a zinc float bowl with an aluminum throttle body. Some were built with a cast iron throttle body and zinc float bowl.

Models

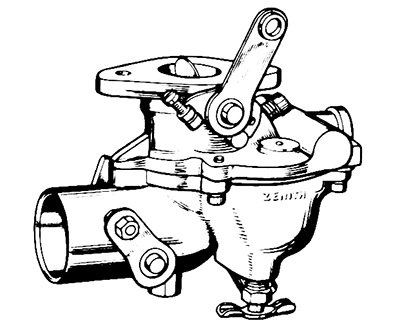

61-161

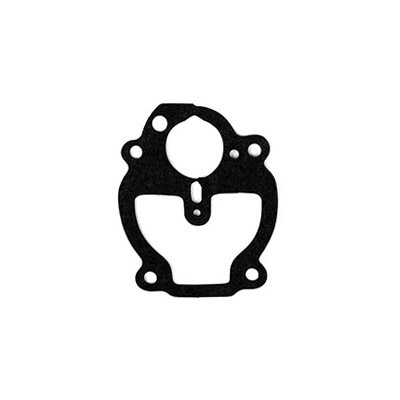

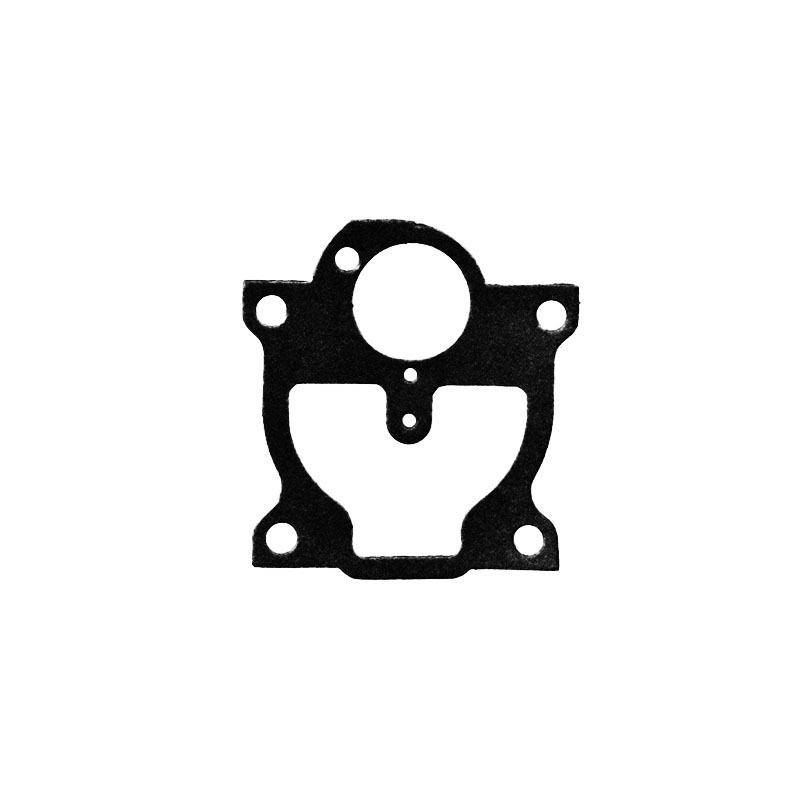

Model 61 and 161 use 4 screws attaching the float bowl to the throttle body from the underside. The main jet adjustment (T-handle), if used, is horizontal. The model can be confirmed from the shape of the float bowl gasket.

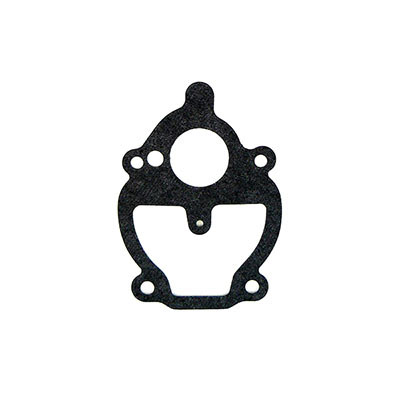

261

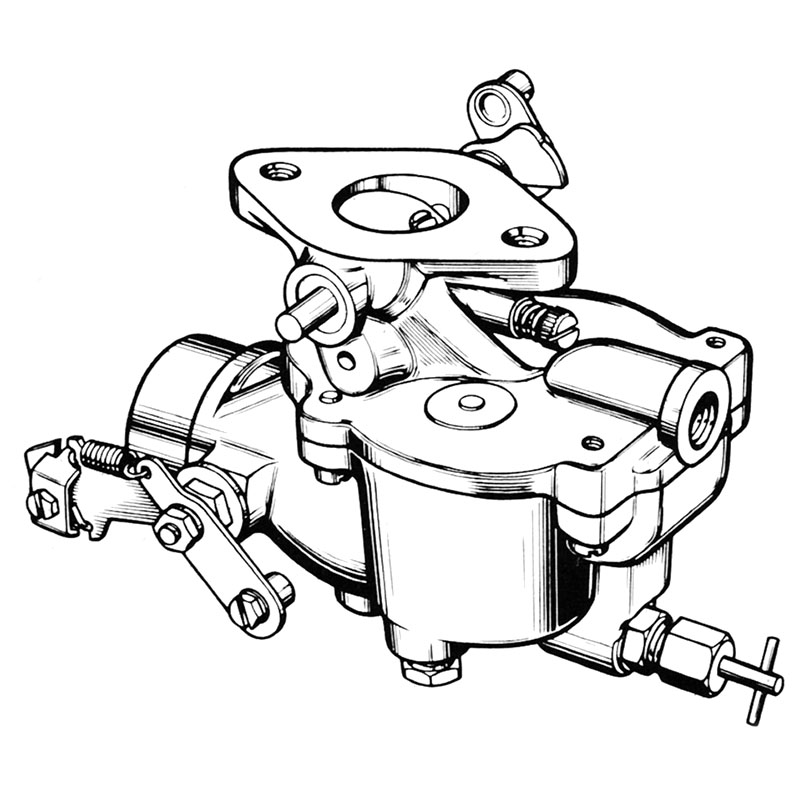

Model 261 carburetors differ from 61 and 161 in having double idle discharge ports (an upper and lower port). They can be distinguished externally by the idle mixture screw being horizontal (61-161 has a diagonally mounted screw).

Some model 261s used on Caterpillar diesel starting engines had a diagonal mounting flange (mounting stud centerline at an angle to the center line of the carburetor) and a special float bowl shape, as shown in the illustration of one of the bowl gaskets in carb kit CK9934.

67 Size 7 only

The model 67 carburetor was made in size 7 only (SAE 7/8" nominal). It was used on a few IHC and Massey-Ferguson applications.

In model 67, the main jet adjustment (if present) is angled upwards on the bottom of the float bowl and the idle mixture screw is diagonal. Model 67 carbs use a reverse idle adjustment, so that turning the screw in makes the mixture richer. Model 267 (size 8 through 10) is covered separately.

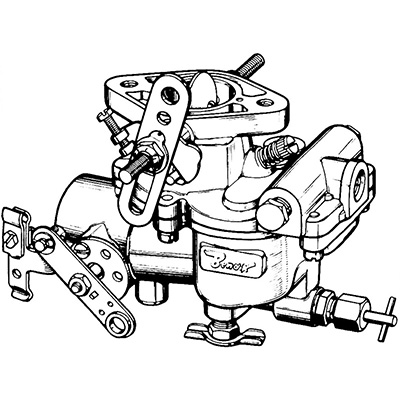

68

Model 68 was made in size size 7 (SAE 7/8" nominal) and size 8 (SAE 1" nominal). They were used on many different industrial applications and were manufactured up to the end of Zenith production in 2025.

Model 68 is generally similar in appearance to 61-161, with a different gasket shape. Later production carburetors used 5 screws to attach the float bowl and throttle body, with the 5th screw at the top front of the carburetor. Early models developed air leaks in this location when the zinc throttle body casting became warped upwards at the front. The throttle body is aluminum on late models. The service gasket is the same for the 4 and 5 screw models.

Needle/seat assemblies came in two different general types, with different threads, so the parts are not interchangeable. Some high-vibration applications (especially Wisconsin) used a spring-loaded needle. Also, there were three different floats used. Some floats used a wind-up spring around the float pivot pin to dampen vibrations. These were used in some rough service applications, like Bobcats and other equipment. The correct service parts are essential and can be determined from the carburetor number.

More Information

How to find Zenith carburetor numbers